CNC Stirrup Bending Machine is a kind of stirrup bending machine. It is also widely used in the building and construction industries. Compared with the normal stirrup machines, CNC Stirrup Bending Machines have a stronger work capacity. And its structure is more compact than the normal machinery. Our Ellsen cnc wire bending machine has yielded a good return in the international market; and it will be a good choice for the building and constructing industries.

GALLERY

VIDEO

Technical Parameter

| Model | HGTW4-10 CNC | HGTW4-12 CNC | HGTW4-12A CNC |

| Single round wire diameter | φ4-10mm | φ4-13mm | φ4-13mm |

| Double round wire diameter | φ4-8mm | φ4-10mm | φ4-10mm |

| Single ribbed wire diameter | φ4-8mm | φ4-10mm | φ4-12mm |

| Double ribbed wire diameter | φ4-6mm | φ4-8mm | φ4-10mm |

| Max bending angle | 180° | 180° | 180° |

| Central mandrel diameter | φ20-30mm | φ20-30mm | φ20-30mm |

| Max pulling speed | 100m/min | 100m/min | 110m/min |

| Max bending speed | 1800pics/h | 1840pics/h | 1840pics/h |

| 2 Servo motor | 11kw+7.5kw | 13kw+7.5kw | 18kw+7.5kw |

| 1 Brake motor | 4kw | 4kw | 4kw |

| 1 motor for air pump | 4kw | 4kw | 4kw |

| Voltage | 380V/415V | 380V/415V | 380V/415V |

| Average electric power consumption | 5kw/h | 5kw/h | 5kw/h |

| Working environment temperature | ’-5-40℃ | ‘-5-40℃ | ‘-5-40C |

| Overall size | 3500×950×2000mm | 3500×1000×2150mm | 3500×1000×2150mm |

| Gross weight | 2.35T | 2.5T | 2.55T |

Why choose Ellsen Stirrup Bending Machine

1.Automatic wire feeding system (CNC).

2.Moveable air compressor design, to ensure better cooling effect, easy transportation and installation.

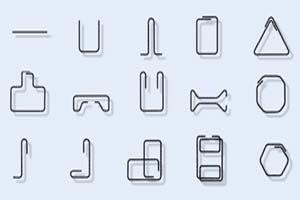

3.Large storage capacity can save 500 processing geometric graphics, high degree automation

4.Aerodynamic design observation door, easy adjustment and maintenance, more security and fast.

5.One care person is enough to operate.

CNC Servo Control System

Multi-Purpose Bender

High-Efficiency Bender

Customization